The structure of the frame building is based on typical nodes connecting vertical and transverse elements to the whole design. The technology of assembling the shield walls considered here will help you when it is built. own house.

When building a wooden frame, used:- Brussia 100x150, 150x150 mm;

- Boards 50x150;

- OSP sheets with a thickness of 9 mm;

- Nails and self-tapping screws;

- Corners, plates;

- Waterproofing rolled;

- Antiseptic for wood.

Basic tools for work:

- Disk or chain saw;

- Screwdriver, drill;

- Handwork manual, ax;

- Hammer, ticks;

- Measuring tool.

- Through metal corners - simply and quickly, but they are not suiced;

- Fastening a word (complete or on Polbrus) - economically, if you do it yourself.

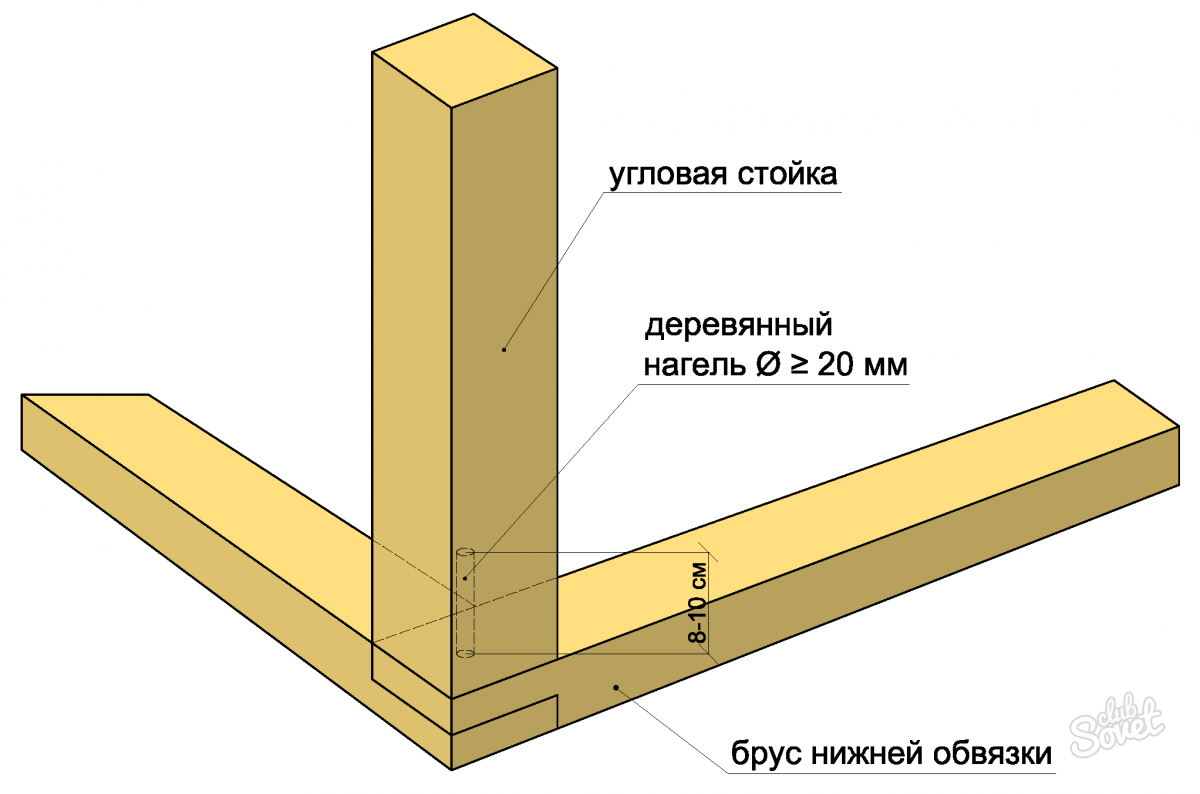

When connecting the length of the vertical racks is equal to the height of the floor, and when the cutting is used, the depth of the groove is added.

File lags are fitted onto the strapping close to the bars of the wall, providing additional durability of the frame. The upper frame is assembled by the same method that the installation of racks was performed below. To increase the stiffness of the structure, the covers are arranged - each rack is fixed with four diagonal bonds. Inclined bars of smaller cross-section are used, placing them along the inner frame plane and leaving the place for the insulation.- In bulk using special metal brackets or corners;

- By placing a block of overlapping on top strapping with cutting groove in a beam or without it.

The first option is more suitable for non-residential attics, the second is preferable to the device of the second floor.

There are two methods of the frame of the frame of the frame sheet:- OSP plates are fixed after the construction of a wooden skeleton;

- Sheetting sheets are made in the construction process.

The latter option allows you to use a smaller number of fasteners, as the frame is immediately strengthened by oriented chipboard. In this case, the construction of walls is carried out by other technology:

- The corner bar is installed on the plumb, it is fixed diagonally with a nail and grabbed a temporary disposal;

- Similarly, the following two racks at the required distance are mounted;

- The horizontal bars are attached at an altitude corresponding to the middle and edge of the plate;

- On the resulting frame is sewn with screws with screws after 100 mm;

- Other vertical supports are set and the work diagram is repeated.

The use of this technique requires the installation of shine only in the corners of the framework.

Frame house building is good because it allows you to make most of the work with your own hands. As a result, it turns out warm and cheap accommodationcapable of serve not one ten years.