The pile foundation is popular in private construction, as it can be erected on a weak ground for multi-storey buildings. During the arrangement of such a foundation, the work related to the organization of the basement of the house is reduced.

Features of the pile foundation

Piles are products made in the form of long rods used to build a foundation. There are several designations of pile foundations, which depend on factors such as the kind of piles, the depth to which they will dive into the ground, also takes into account the location of the piles under the future house and the framework of the Turks.

In the process of arrangement of the foundation of the house, such piles can be used:

- Ready. At one side, a pointed end have a pointed end, thanks to which they are immersed in ground using special techniques.

- Printed. Piles not only are used in the form of finished products, but also manufactured in the soil. To do this, a formwork is installed in the well, metal straighteners are immersed with the purpose of reinforcing, and everything is poured with concrete.

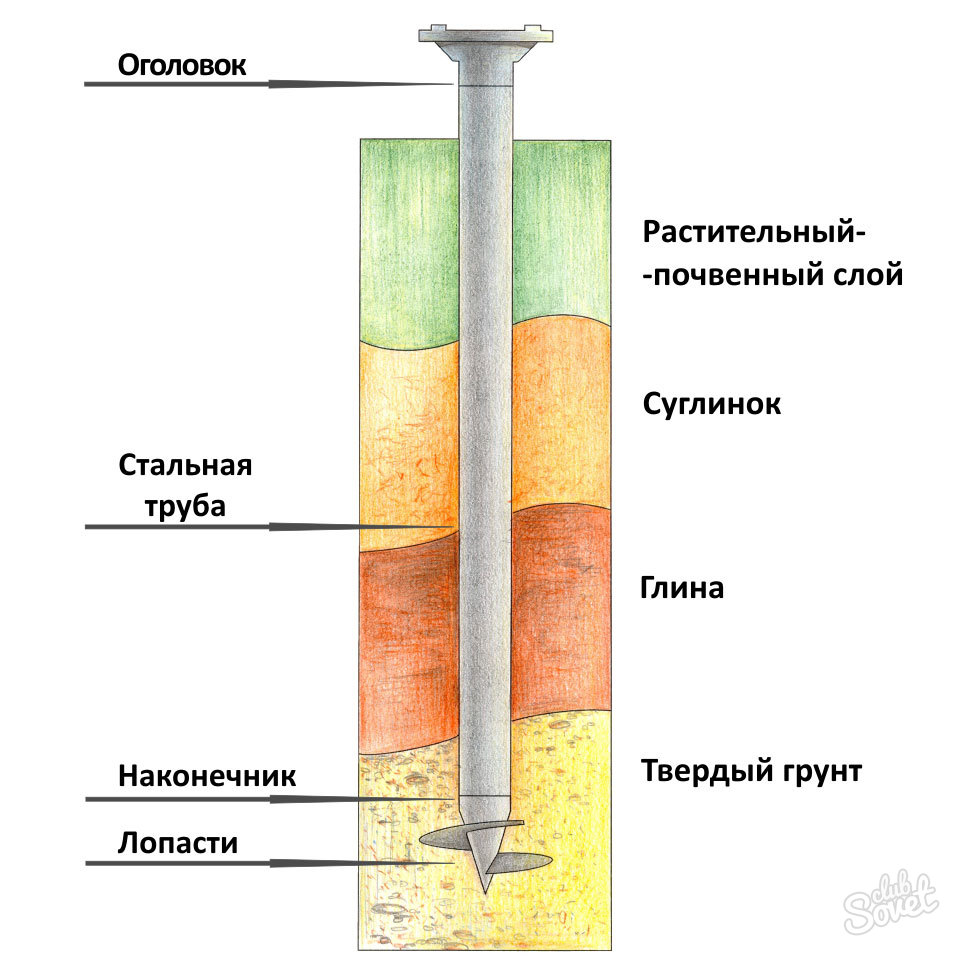

- Vintage. Products got a name due to its form, which reminds drill. Piles are installed by manual twisting into the ground.

- Rough iron-boring. Such piles is a reinforced concrete rod installed in the well.

In the land of piles can be placed in this way: as separate supports in a single order; ribbons in a row under the bearing wall to distribute arising loads between them; Under the supporting columns, located bushes. Installing piles taken in a vertical position, but on the ground with an excessively movable soil is possible installation of products at an angle.

Material for making piles

Depending on the material that is used in the manufacturing process, piles are such:

- Reinforced concrete. Such products can be made directly in place where construction work is underway. This uses concrete, whose mark should not be below M200.

- Steel. If the product has a length of more than 3 m, and its diameter is 10 cm, then crane equipment will be needed during the installation process. In addition, some inconvenience is caused by the need for metal processing with a special composition to create an anti-corrosion coating. Yes, and the material consumption will be big.

- Wooden. For the foundation device, smooth pillars are used, purified by the diameter of which - up to 34 cm, and the length is up to 8.5 meters. To make piles, conifer breeds are used, which have a greater hardness to which larch, pine and fir. Despite the fact that this is the cheapest raw material, use wooden products for the construction of the foundation rarely, as wood is capable of rapidly subjected to rotting. Although today you can choose a quality drug intended for wood processing.

Use of pile foundation

The need to build grounds from piles occurs in one of the cases listed below:

- A weak soil prevails on the plot. These are bunched soils, vegetable soils, which contains humus. It is advisable to build the pile foundation and on the lesid soils whose stability is lost when the water approaches. Also, clay and loam are also classified to this category, which is characterized by fluid state, and sand-clay type grounds are oversaturated with water. In this situation, with the help of piles, the load, which turns out to be a building is transferred to deep soils that are more dense.

- The house is planned to build on a dense soil. After all, piles will help reduce the scope of work, and, accordingly, and significantly save on digging care, export of soil and backfill. But when the tape is erected, it is worth an order of magnitude more.

Preparatory work

Before the foundation device, be sure to calculate the pile foundation:

- Determine how many supports will need to be placed with what step to place them. At the same time take into account the material of the future building and, accordingly, its approximate weight. Remember: the more the weight of the building, the piles should be placed more often. The optimal option is considered to be a step that reaches 1.5-2.5 m.

- From how massive the structure will also depend on the thickness of the piles, which may have a diameter of 57 to 133 mm.

- When determining the depth of the ploups, the climatic features of the region and the fitness of the soil are taken into account. In addition, this indicator may differ for each single pile. In private construction, piles are used, the length of which is 1650-3500 mm.

Welding well drilling

Piles are installed in special wells, which should be done in this way:

- For drilling, the pits are used manual borrow - electric or gasoline, since manually can be pulled out only about 3 m.

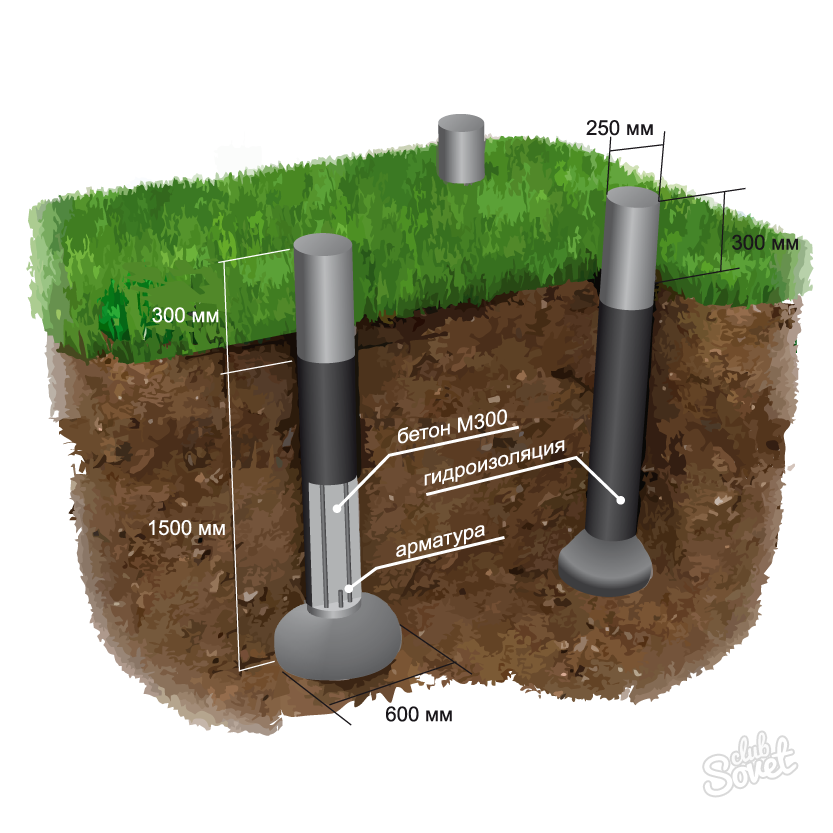

- Wells should have a diameter of about 30 cm, and their depth is to reach 5 m. To increase the bearing capacity of piles, it is recommended to expand the base of the foundation by using special drilling heads.

- Remember that piles when installing should have a sufficient length for passing the freezing zone at least half a meter and overcoming the weak layers until the dense layers of the soil are reached.

- If a lot of water appeared in the well, it should be pumped out by the pump.

Mounting formwork for foundation

If the terrain is dominated by bulk soil, then the formwork should be created to protect pile from destruction. Otherwise, its strength will be low, since when the concrete mixture is pouring, cement milk will be seamless, and roughness is formed on the surface, which will lead to the holding of moisture inside the product. A peculiar formwork for pile is a pipe made from a regularoid folded in several layers. It should be longer than the well for 200-300 mm, and its diameter must correspond to the diameter of the pit. Instead of such a formwork, you can use a conventional asbestos-cement pipe. If the soil is dense, the formwork can only be installed in the pile's glove.

Pile reinforcement

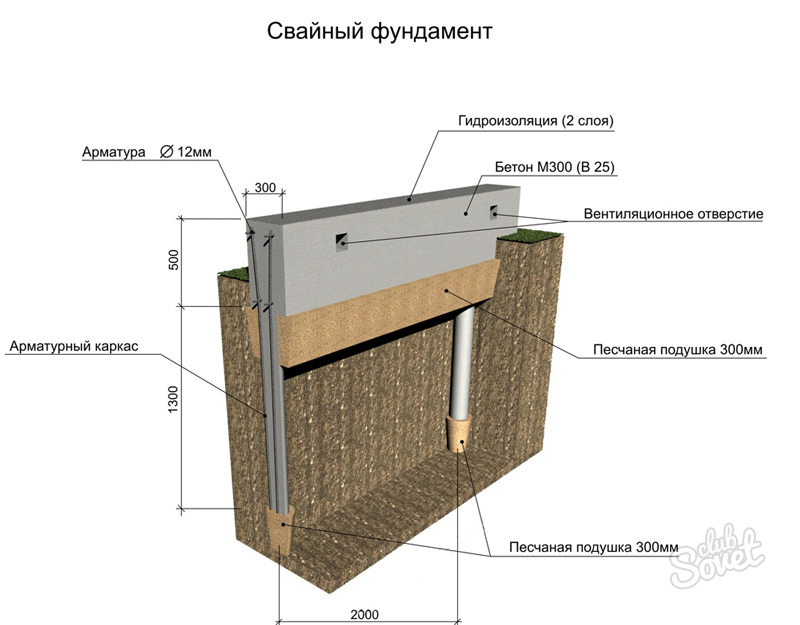

In order for the pile foundation to have good strength, it should be strengthened by reinforcing rods. To create a reinforcing frame, you will need 3-4 rods, the diameter of which is 6-8 mm. Create them between themselves clamps to get a single design, the fastening step is 500-600 mm. The resulting product is placed in a well for the whole depth, in addition, it should be raised over it. Another part of the head of the frame should be touched. The reinforcement frame should not touch the formwork, leave a small gap, reaching 3-5 cm.

Concreting pile

Now you can go directly to the concrete pouring procedure in the well. It is better to give preference to heavy concrete, the fillers of which are quartz sand and solid crushed stone, whose size is up to 20 mm. The solution is made by layers that reach 40-60 cm, sealing them with a vibrational installation. Do not interrupt this process, since in the place of contact of the frozen and fresh concrete, the monolith is not formed. At such sites there are "cold seams", in their characteristics similar to cracks that weaken the whole design.

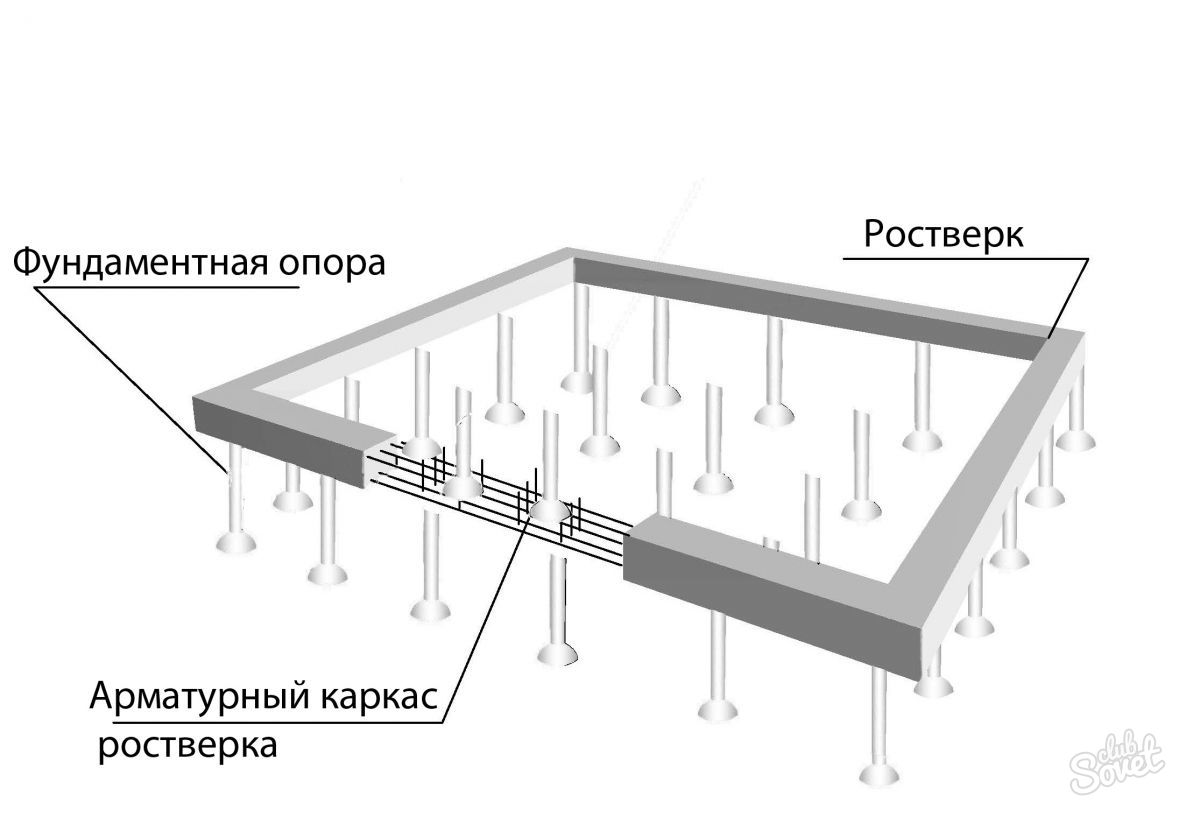

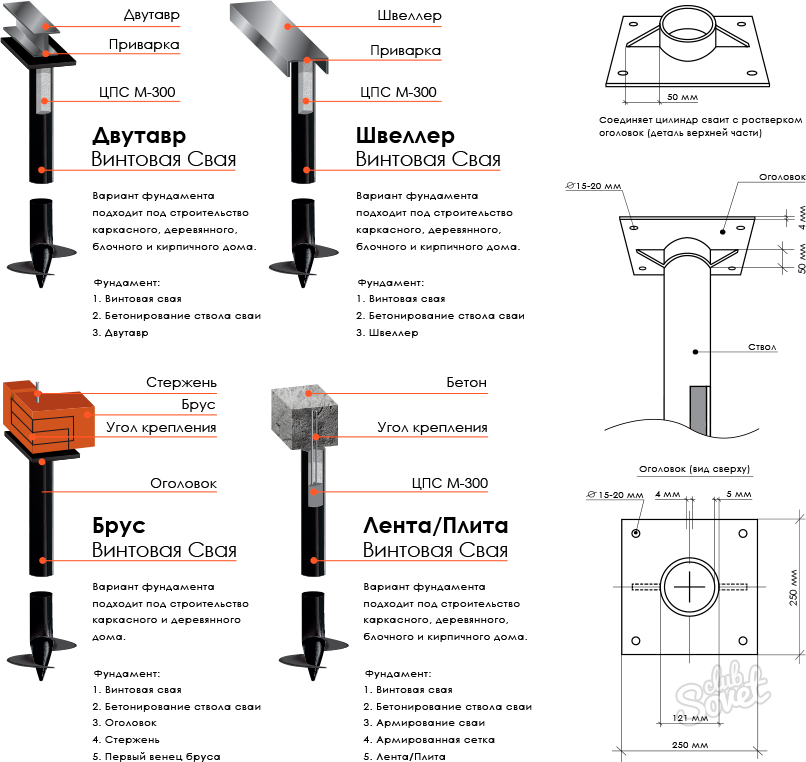

Scarlet for pile foundation

To connect the piles among themselves to a single construction, paint closure, which can be deserted partially or completely or completely, or not to plunge at all:

- If you stopped on the first type, you should dig a trench around the perimeter of the structure, which should be located between the pile tempes, and under the inner walls.

- At the bottom it creates a rubbed pillow under the foundation, the upper boundary of which should reach the top of the pile.

- Then the runneroid is placed on which the formwork is installed with struts.

- At the next stage, the grip is carried out, the rods of this frame must be combined with rods protruding from piles. Special attention is paid to the lower and top of the woodwork.

- Now it remains only to pour a solution, not forgetting its seal.

Works on the construction of unlightened paintwork are similar, but in this case it is not required to dig in this case, and put the formwork directly on the site, falling asleep in her layer of sand. For the closure of the gap, which is formed between the soil and painter, protecting the space from garbage from entering and sediment is equipped with a break. It remains only to wait until the Scarlet dials the strength, for this it will take about a month.

Before mounting the walls of the building, check the level of the framework, align the surface if necessary, using cement mortar, and measure the diagonal of the sides.