Tools that are designed to drill metal products, very quickly lose the sharpness of their cutting part. This is especially true of spiral drills of various diameters, and this is evidenced by a sharp grinding at the beginning of work. If it is not possible to restore the initial geometry of such a tool in a timely manner, then in a short time it will come to a dissent. Consider how to sharpen the drill spiral using an electric machine with a stone (grinding circle) or electric drills outside production conditions.

Spiral Drill Processing Options

The method of restoring the sharpness of the cutting surface is determined by the form that the rear part of the metal drill must be given. Sharpening happens:

- Conical (cylindrical): preferable for drills with a diameter of more than 3 mm. The angle on the top of the cone is equal to zero.

- Single bed: It is performed on drills up to 3 mm in diameter. Rear surface treatment is performed in the same plane. The estimated sharpening angle lies between 28-30 degrees.

- Two perception: each of the rear surfaces, from which the drill is, is sharpened separately. Processing is performed by the end of the grinding wheel, which ensures increased accuracy of work.

Training

For home, spiral drills of small diameters up to 16 mm are usually used, and we are talking about. The ideal option for sharpening such a drill will be processing on a sharpening machine with a stone. If there is no machine, then you can replace it with a grinding machine or an electric drill, while pre-fixing the tool. The goal is to obtain a rotating stone or grinding disk (circle). Preparation for drainage:

- We provide eye protection in the process: This will require glasses.

- Cooking a tin can or a cooling solution (machine oil or water suitable). When sharpening the drill is heated, and it must be cooled as needed. Overheating tool in the process of sharpening threatens the loss of their cutting qualities.

Conical sharpening method

A spiral drill is sharp in several stages: first processed rear, then the cutting part. Let's start with the rear:

- We press the surface of the drill to a grinding stone or a circle so that there are no gaps.

- Important: During the work, the angle when sharpening, keep all the time the same.

- We look at the tip of the drill on the side: if the rear surface processing is carried out correctly, then you will see a smooth cone.

- Next, the cutting edge is hurned: also strictly observe the sharpening angle.

- The next operation goes the refinement: smoothing the small jar of the rear surface, which makes it possible to increase the wear resistance of the product. Follow the jumper at the end of the drill, for a tool 8 mm with a diameter and less, its size should not be more than 0.4 mm with proper sharpening.

- For the drill larger diameter, the size of the jumper is 1-1.5 mm.

General recommendations for work

The spiral drill is sharpened by the rear edges, which must be absolutely the same after processing. In manual mode, it is very difficult to do, as you need to withstand a certain angle and the form of drill when working. Before starting sharpening the drill, it is recommended to practice on non-working spiral drills. It is necessary in order to "fill the hand." By inserting such an old drill in a drill, you quickly orient how the sharpening was performed correctly. It should also be remembered that the drilling is made by the side edges of the instrument.

Sharpening comes down to restoring the factory shape of the cutting part of the drill. Do not forget about the basic rules for processing drills with attacks from different alloys: the harder the material of the tool, the lower the sharpening speed should be.

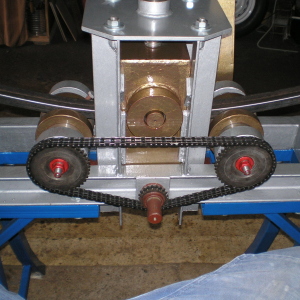

You are generally aware that on Ava to the article, you hang a photo drill photo. The article is called "how to sharpen the metal drill" Maybe you have such a move, but I leave you, forgive

Hello! This is really my defects. The spiral metal drill comes with a jumper in the middle instead of the tip, and in general they are identical. My apologies. I hope the information in this article was useful to you.

Sharpening is thin, and about sharpening you need to remember constantly if you deal with cutting tools.