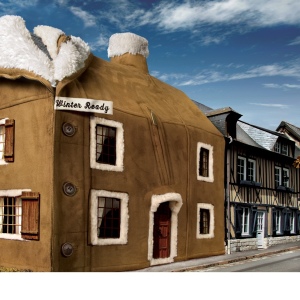

The dream of every person is a house, reliably protected from all adversity, warm and cozy. To not be afraid of cold and drafts in the coldest days, fumble in advance about reliable housing insulation. We will get acquainted closer with the heat insulation procedure at home mineral wool.

Features and types of minvati

More recently, the first place in the list of the most popular materials for the insulation of houses occupied a foam due to high thermal insulation properties, light weight and a democratic price. But the term of its useful service is low, limited to 20 years, so it began to push out other thermal insulation materials, in particular mineral wool. For facades, minvatu made in the form of plates are used, which is explained by the convenience of its installation and the required density level - at least 80 kilograms per 1 cu. meter. As a rule, the plates have dimensions of 0.5 per 1 and 0.6 to 2 m, their thickness is 5/10/15 cm. The second option is considered to be the most suitable for the insulation of houses.

Depending on raw materials, distinguish stone, slag and stealth:

- Glasswater. The material can be operated at a temperature that fluctuates from -60 to +450 degrees. Since it is characterized by high fragility, sharp fragments of fibers easily penetrate through clothes and provoke itch, then during operation with glass gamble, you need to use dense mittens and protective glasses.

- Slag wool. For the manufacture uses domain slags. The material is inherent in high hygroscopicity and the ability to absorb water vapors, so it is undesirable to use it for the insulation of the facades.

- Stone (basalt) wool. Its fibers do not rsive, so the mounting of stone wool is not associated with inconvenience. The material is resistant to critical minus and possess temperatures, is characterized by high vapor permeability, because it has a porous structure.

The advantages of mineral wool

We list the advantages of minvati in front of other heat-insulating materials, thanks to which it is chosen for the insulation of houses:

- High thermal insulation properties.

- Resistance to ignition. In the case of a fire of minvat, it will not ignore, since its melting temperature exceeds 1000 degrees.

- Parry permeability. Couples can penetrate under the insulation, and condensate, which occurs, is immediately removed.

- Ability to absorb noise. Due to the porous structure of Minvat, acoustic properties are inherent.

- Resistance to mechanical damage and deformations. This property contributes to an increase in the service life of Minvati several times, if you compare it with another material used for thermal insulation of houses - foam.

- It is not of interest to harmful animals. Mineral wool does not become an object for rodents.

Disadvantages of mineral wool

In the course of the research, it was found that carcinogenic substances were included in mineral wool, representing the danger and harm our body. However, they are present in negligible quantities, and subject to the rules of installation and operation of the material they will not become a real threat. Nevertheless, it is worth purchasing insulation only from proven manufacturers who adhere to all necessary requirements for the production of products.

Wall insulation Minvata

With the help of mineral wool, the outer thermal insulation of the walls is usually carried out, since in this case the inner area of \u200b\u200bthe house does not decrease. In addition, vaporizolation with thermal insulation indoors can cause ventilation deterioration.

Preparatory work

Consider what work is preceded by the insulation installation:

- In the course of preparation for fastening mineral wool, it is necessary to carefully clean the facade from pollution, traces of rust and plots with mold. If there are leaks of cement, they must be removed.

- If there is an old coating that paint or plaster stands, it should also be removed.

- Metal pins, any projections and protruding items to achieve a smooth and smooth surface are removed from the walls.

- In addition, you have to remove all the communications to which the brackets, drains, wires, pipes are counted.

- In the presence of chips and cracks, they are closed with a solution.

- After the freeing of the working surface, it should be covered with anti-grab.

- At this stage, we mark the working areas with the help of sturdy cords that must be over the surface boundary by 1 centimeter. There are cords in a horizontal, vertical and diagonal direction.

Montage Minvati under Siding

Features of thermal insulation facade house under siding:

- After preparation of the walls, install a starting profile along the base, which will perform the support guide for mineral wool plates and maintain the lower row. For fastening a profile to the wall, a dowel is used, which should be located at a distance of 60 cm from the ground.

- Attach the moisture protective film output from the insulation and not missing it back.

- Vertical guides are fixed on top. In the space formed between them, and you will lay the insulation. Depending on the size of the plates, the fastening step should be less than 1-1.5 cm, since the minvat must sit tightly.

- For fastening plates of mineral wool to the wall, special dowel fungi is used.

- After mounting the heat-insulating material, you should equip vaporizolation to protect it from the harmful effects of moisture. For this, a vapor barrier film will be used.

- At the next stage, sending guides to ensure a ventilation gap and fasteners of decorative finishing material, in our case - siding.

Montage Minvati under the plaster

The process of insulation of the facade of mineral wool under the stucco is happening:

- Set along the base along the pre-scheduled line profile. Dowels are used to fix it.

- For gluing minvati, special dry glue is used, which is packaged 25 kg and is prepared by adding cold water. After applying glue on the insulation plate, it is installed on the starting profile. Then the Minvatu must be attached to the facade.

- Do not wait until the adhesive make up, and immediately align the glued slab. And you can start mounting the second and so on. After the arrangement of the first row, the second, laying the plates, like with a brickwork, overlapping the joints.

- After mounting the mineral wool, strengthen it additionally, using the building fungi, which should be installed at the corners and in the center of the plate.

- Next, we carry out the reinforcement of the surface, starting with the corners, to protect the material from the destruction and imparting the surface of the smooth view. To do this, use a special corner with a glasswork. After a day, you can start strengthening the main surface. Apply glue to the surface for mineral wool. Then secure the fiberglass, pressing it with a spatula. The grid is located with the allen, which should be at least 10 centimeters.

- At the final stage, the facade is placed. When using polycementary plaster, it is impossible to interrupt the workflow in order to avoid the formation of joints and reduce the quality of the coating. After completion, the surface from the rain should be protected: for conventional plaster - 1 day, for color - 3, with high humidity on the street - week.

Useful advice

The insulation of the facade of mineral wool is usually carried out with air humidity not exceeding 85%. If the weather is rainy or foggy, then it is worth refreshing from the ventiy, as the design can collapse. At air temperature, which is more than 30 degrees, it is necessary to stop working and close the insulated sections, using the dark heat insulating fabric, otherwise the formation of cracks in the material is ensured. If you plan to stretch the heat insulation procedure of the facade the next day, do not forget to close the entire surface that you have already been insulated.

And finally, remember that no pollution and even dust should not fall on the working surface.