Planting the ax on the axle must be correct. It will provide an employee of a continuous rod of firewood, without distraction to the flourishing time from time to time. Most often, newcomers do not know many tricks that could effectively help when repairing an ax. Namely, the selection of optimal species of wood for the handle of the ax, additional strengthening materials.

How to plant an ax on a pipeline - wood preparation

- Wooden selected orange Bar from which you need to make a handle for the ax. A simple pencil is planning a future form. The axle can not hang out, and should be tightly into the ax. Therefore, the bar is cut a little large in size than you need not to miss the size. Can always be reduced, but for a dense shrinkage can And wedges do not help.

- The method of applying, pencil outlines the contours of the eye, as well as places plun..

How to plant an ax on a pipeline - the process of nozzle

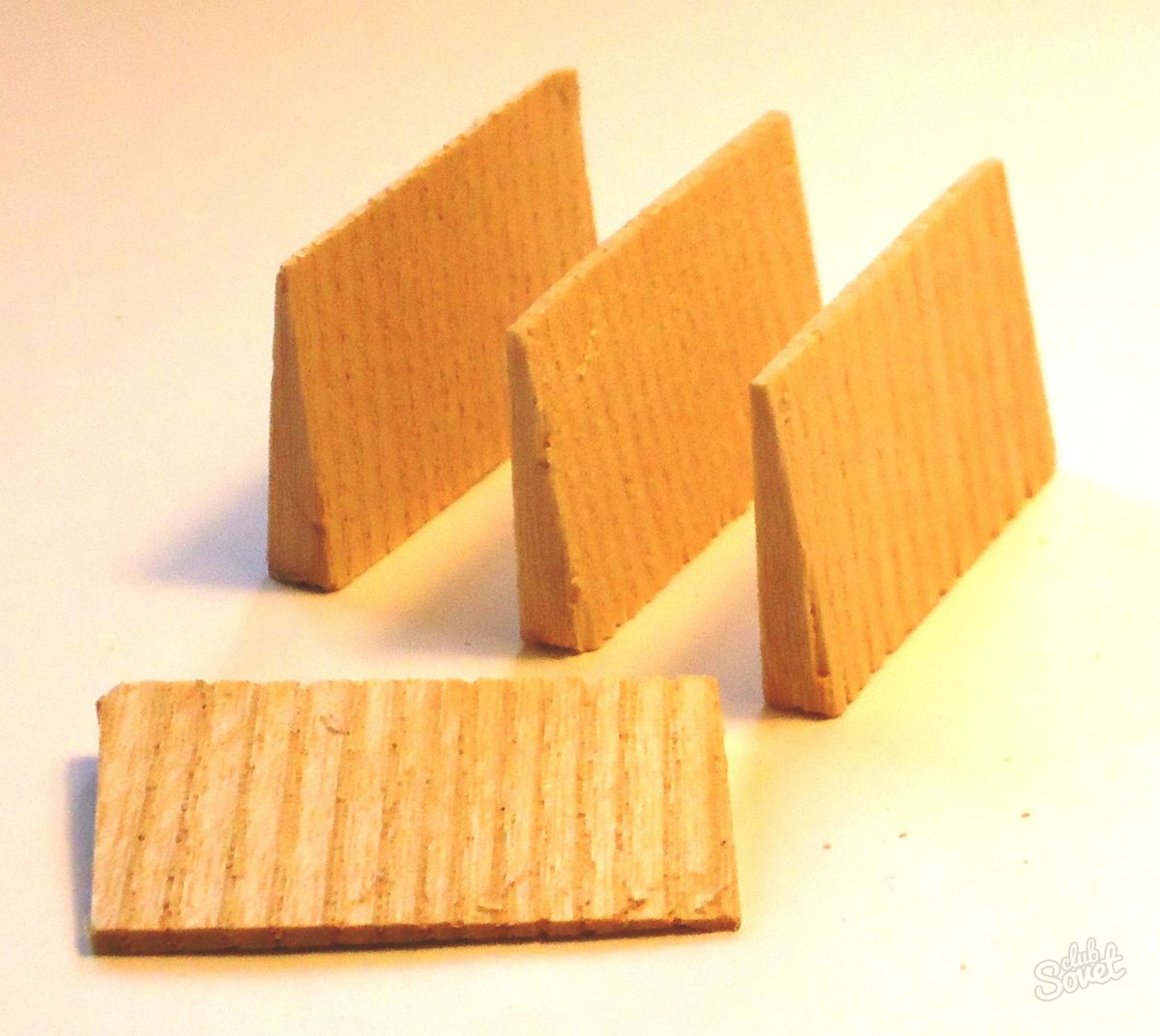

- So that the ax does not hang out, craftsmen make wedges, metal or wooden. Metal wedges are very difficult, it is easier to buy them in a specialized store. Wooden wedges are made both with their own hands and purchased.

- Further on the axle is placed the height of the ax. At this distance is added about 5 mm, then they can be cut off, or leave. It is noted the deepest place on the handle, which will be sinking the ax.

- The turn to measure the depth of cuts under the wedges. Such recesses will be less (shorter and already) than the wedges themselves, for a reliable shrinkage. Recesses are cut out with a saw for metal with minimal drank Woods.

- After the markup is ready, made cut, the handle itself is being finalized. Rezlithugovy Rounded forms nazjak Miscellaneous grain.

- When the ax is conveniently sits in his palms, work continues in the area of \u200b\u200bsawing. Carefully removed the extra millimeters, adhering to the tight entry into the ax.

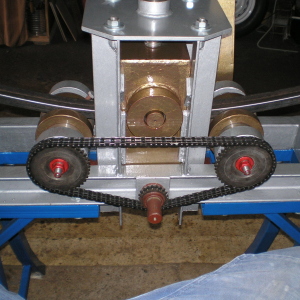

- The process of nozzle passes a stupid non-footing subject. For these purposes, the board is used, or rubber, weighted Cyanka for tiles that will not hurt the tree and the metal part.

- During the nozzle goes unnecessary tree. According to these, I can define number Exclosures that need to be removed.

- Shrinkage occurs gradually. Grinding extensible material is done using a sharp knife, skins or grinders with Lephetsky emery Nozzle.

- The tight nozzle of the ax serves as a guarantee of a good result. When the nozzle reached the maximum depth, the excess tree is removed, the wedges have to be driven. For this random tapping disconnect All design.

- The ax is not removed using a metal hammer and knife. This is done by focusing in a solid surface.

- To crack during plun. I did not go deep into the handle, the through hole was racing 5 mm.

- Wooden wedges are attached to epoxy resin, and then pull them on almost possible. Metal wedges rarely sit on epoxidbut drive tightly. To the ax that the ax does not burst during the final stage, it must be correctly hardened. The nozzle is made by Cyan.

How to plant an ax on an ax - Important rules

- For the manufacture of the handle for the ax, a tree is braked with bitch. While working with such an ax is a high chance that he cracks together bitch.

- The Handle of the ax should be as comfortable as possible, as it will narrow out from the fingers while working. At the end of the handle there is a small bending for the rest of the hands.

- If the work does not wait and the ax was urgently needed, the use of fresh wood is allowed, but with caution. After a while, the handle will dying, and starts hanging out. In this case, wedges are put, plant on seals, but only after complete drying.

- A brightly painted handle is the best track alarm, if the ax is lost in the grass.

In order for the process to go through the rules, you need to know which tree of the tree is better to pick up for the ax. The most strong and reliable will be axes from oak, acacia, pears, mulberry, ash, cousl, birch, maple. Wood should not be fresh. Only after a year of natural drying in a dark, dry room, a piece of wood can be considered ready for work.