The household version of the profile tube is manufactured by analogy with factory models, a little simplifying design and using affordable materials.

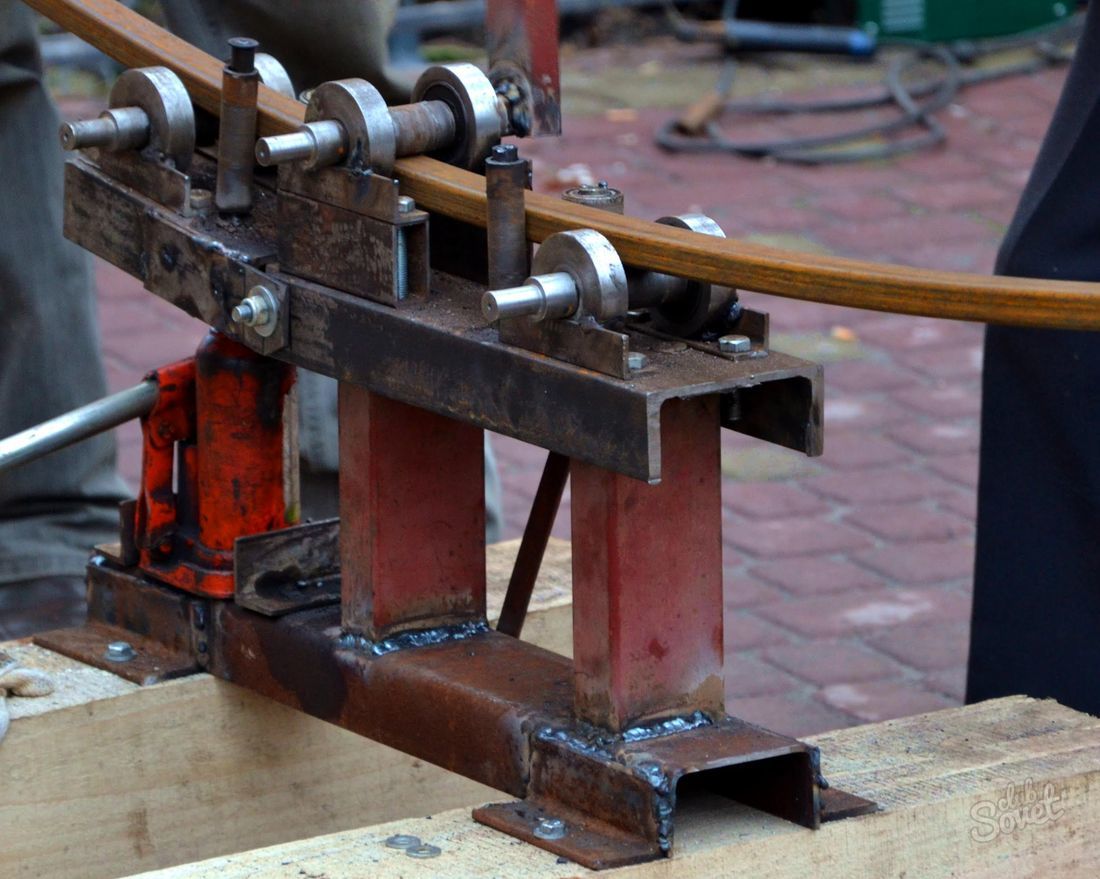

Device of homemade pipe bending

The base of the machine for flexible profile pipes is the rigid frame, inside which three rollers are placed: one clamping in the middle and two bypass on the sides. To create a clarifying force, the pipe bender is equipped with a screw mechanism, the pulling of the workpiece is carried out by means of a rotary handle, fixed on the axis of the central roller. A homemade device allows you to bend profile pipes up to 60 mm wide with minimal bend radius in 90 mm.

Used tools

For processing metal blanks, you will need:

- Welding apparatus Inventory;

- Powerful Bulgarian;

- Drill or drilling machine;

- Files of various shapes;

- Measuring and marking tool;

- Consumables - metal drills, grinding and cutting discs.

Production of the base

For the side of the pipe bending, the steel P-shaped channel with a cross section of 80x80 mm, having the wall in 4 mm and thicker, is selected. The markup of the parts and cutting of the grooves is made with maximum accuracy, observing the alignment of opposite elements. Large holes are drilled in a few approaches, starting with a drill with a diameter of 6 mm and gradually increasing the caliber of the nozzle.

Production of the core of the screw mechanism

The housing is two identical parts cut from 6 mm sheet steel and connected at the top with a nut-platform. Long through grooves serving guides to move the roller perform the following method:

- Accurately place the workpiece.

- Drilled along the edges of the groove hole.

- Make spanking straight rods.

- "Conduct" the groove with a file.

The velocity platform is attached to the walls of the housing using the M8 bolts or weld.

Rollers for pipe bend

The most complex elements in the homemade bending machine. There are three solutions to the problem:

- Purchase of finished products that are sold as replacement parts for factory benders.

- Order with Turner for the manufacture of components in their drawings.

- Purchase suitable bearings (for example, the vehicle hub) and selection for these shafts.

The main drive roller is fixed in a holder connected to the rotary screw.

Screw and handle

Jackscrew made of iron round bars of 24 mm in diameter to the threaded portion, and 16 mm for the handle. Length last selected in the range of 40-50 cm - sufficient in most cases, and with the need for more effort to lengthen the lever meter tube. Handle rotation of the drive roller can be of any design, most importantly - comfortable and durable.

How to use the bender

With homemade machine for bending profile can be varied to produce scaffolds and complicated bent elements.

Working with benders:

- Plumbing fixture is fixed on a workbench.

- Shaped tube is placed on the support shafts.

- Clamping screw central roller is lowered completely into the preform.

- Making more 3-4 turns, the rotation of the handle is pulled the product of the bending length.

- Not pulling the profile clamp is lowered below the workpiece and again rolled.

- Repeat the steps until the desired fold.

Achieve the desired radius of the workpiece, moving the side support rollers in the grooves of the housing.

Simple, but very reliable tube bender costs much cheaper than a similar mechanism of factory production. The video shows a device of another device, which allows easy bending reinforcement strip or profile.