Let us examine in detail the design of the vibrating table and look at the order of manufacturing at home this unit required for the forming of concrete products.

How does a vibrating table

Device consists of three main parts:

- A rigid metal frame.

- Attached to the shock absorbers countertops.

- Electromechanical vibrator.

Molds with a solution positioned on the table top, which starts to vibrate when the engine starts. After a short time, the mixture is compacted and discharged from the air, and the concrete components are uniformly distributed throughout the volume.

Tools and materials

device is needed for the manufacture of:

- Welding inverter;

- Drill;

- Bulgarian;

- Flooring tool.

Materials used:

- Steel Area 50h50h4 - about 6 m;

- The tube of rectangular section 20x40 - 6 m;

- Sheet metal 120h75 4-6 mm thick;

- Springs or rubber cushions - 4 pcs .;

- Small pieces of inner tube diameter smaller sized springs;

- Bolts and nuts.

The construction of the frame

The main requirement for the supporting part of the machine - the strength and the realization can be any. Simple progress of work on the production of reliable basis is as follows:

- Cut from the corner of the four legs of the table length of 75-80 cm.

- Prepare two tubes of the profile of the workpiece and two 60 cm to 1 m.

- weld of pieces of profile upper frame and welded legs.

- Cut to the size of the lower rungs of the rack and connected by welding table.

- Fix the corners base "glass" under spring made from scraps of pipes.

Making the cover with their hands

Table top machine will rest on the spring pads and held at the expense of rail.

The procedure works:

- Constructing a frame similar stationary surface table, reinforcing the structure with additional ribs.

- Arrange the platform for placing the motor on the basis of its dimensions.

- Is welded at the corners of the retaining stops - the ring of steel pipe.

- Welded on the ribs sheet metal.

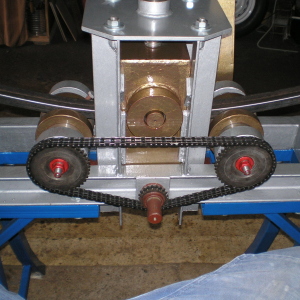

Making a vibrator

The power unit is selected depending on the size of the movable table top - on 1 m² of the surface you need about 1500 W power of the electric motor. Eccentrics are welded on the motor shaft - bolts with a diameter of 12-14 mm with screwed nuts, which are subsequently adjusted by the amplitude of the vibration, shifting through the thread. An easier way is to purchase a factory vibrating platform type. Its design already provides for the possibility of changing the power of oscillatory movements.

Assembling vibrationtola.

The engine is screwed into place by bolts, fixed with locknuts and set the cover on the springs. It is advisable to breed the plates for anchors. Next, collect the electrical circuit, connecting the feed cable through protective automata and arranging the grounding of the unit. Ready vibrationtol is tested for performance, adjust the vibrational amplitude and check the stability of the design as a whole.

The described device is suitable for a private farm, and its engine can be applied on homemade vibroplite in the process of concrete work.