One of the most popular and common coatings on the floor is linoleum. It is used in residential, and in public premises, as it is an excellent compliance with the price and quality. Now on the market you can purchase a linoleum of all kinds of variations of colors and patterns that will satisfy for every taste and cost. To lay the linoleum with their own hands, do not need special knowledge and construction skills. In this article, we will tell you how without much effort to cope with the laying of linoleum at home.

Types of linoleuma

- From natural materials. Environmentally friendly material, resistant to various types of bacteria, does not absorb fats, low flammability;

- Polyvinyl chloride. Release in several types: on foamed, fabric or heat-insulating basis. One minus is, a strong shrinkage and a specific smell;

- Rubber. Made in two layers: the bottom of the used rubber or bitumen, and the upper part consists of a synthetic rubber. Resistant to moisture and well plastic;

- Nitrocellulosic - consists of a thin layer of nitrocellulose. Elastic, moisture-proof material, the disadvantage of which is high flammability;

- Alkyd, made on the basis of woven material. Excellent sound and thermal insulation material, the main disadvantage is fragile in operation.

Linoleum laying methods

The basis of the floor for laying linoleum can be concrete or wooden. The main condition is the smooth surface, in the case of irregularities, the linoleum is rapidly wear out. Consider the detailed stages of the preparation of the floor for the floor.

Preparation of concrete base

To do this, form a homogeneous surface without cracks and irregularities. One of the ways to prepare a concrete floor is a screed, you can also use the technology of a bulk self-leveling gender. The main thing is to remember that the surface height differences on 1 meter should not be more than 2 millimeters.

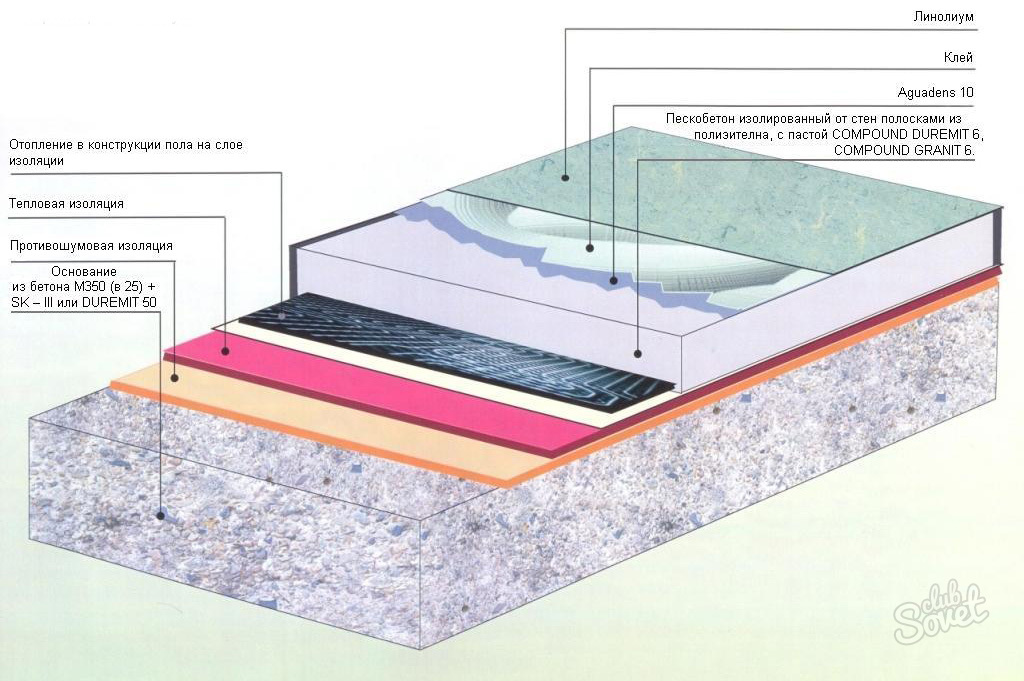

If you decide to get a linoleum with thermal insulation, then it is better not to adjust it on a bare concrete floor. First you need to put sheets of chipboard or plywood, and they already have linoleum.

Before laying sheet material, it is necessary to pave waterproofing. To do this, it is necessary to buy a polyethylene film with a thickness of 200 micrometers and pave the brass at about 20 centimeters, not forgetting to make the wall visits about 5 centimeters.

For sound insulation, it is possible on top of a polyethylene film, paved leaf foamed polyethylene, which must be laid with gaps between sheets of about 1 millimeter.

Preparation of a wooden basis

To begin with, using a construction dryer and a trowel, you need to remove the old paint from the floor surface. To chain joints on the entire area produce cyclishing, and to eliminate large irregularities (more than 1 millimeter) use grinding machine. After that, you need to span all the joints between the boards or lay the sheets of plywood or chipboard from above. In the first case, you will need much more time. But this option is suitable for new floors, where you do not need to close the joints between the boards and that will not be strained or creaked.

The loss of plywood or chipboard sheets is a more practical option, after the use of which, it turns out a smooth surface. At the time of laying, remember, to avoid in the further screen, there should be 0.5-1 millimeters of the gap between the sheets. It is also no need to sharpen a layer of waterproofing, as the tree must breathe, and it is required to remove moisture when it occurs. If necessary, you can lay on top of sound insulation using foamed polyethylene.

Laying linoleuma

First you need to determine the dimensions that you need. To do this, you need to measure the size of the room (with a margin of 5-10 centimeters), multiplying the length of the width, not forgetting the depth of all the recesses. So we get the square of the room. If the size of the room exceeds the width of the buying linoleum, it must be chosen so that the docking of the pieces was in the middle of the room.

After the acquisition, linoleum needed for the day, and preferably two, spread out on the floor for alignment. This process will prevent swollen after laying.

To be cut linoleum, you will need:

- roulette,

- building a knife or sharp scissors,

- double sided tape.

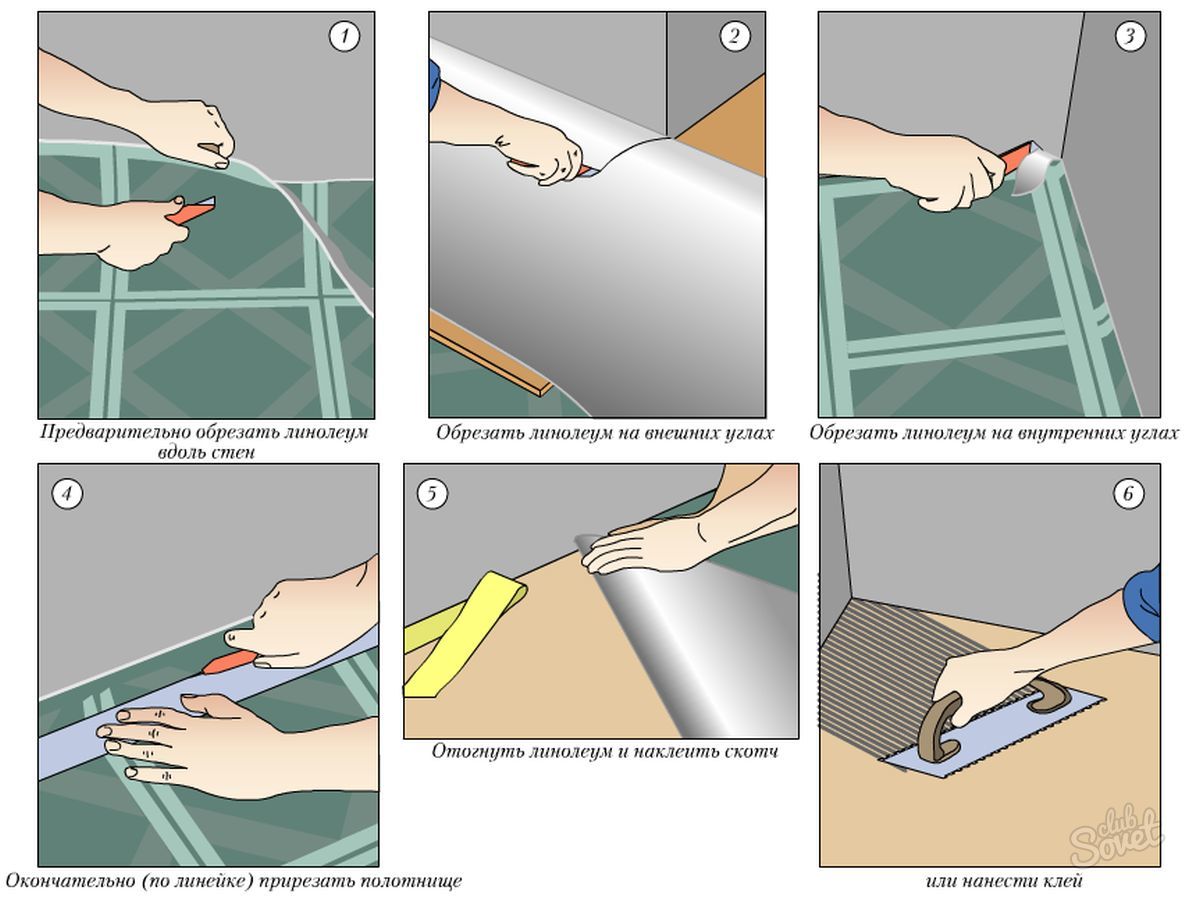

Begin to trim the surplus should be with large pieces, leaving a 2-3 cm margin. After that linoleum is supplied to the corner, we mark the back of the abutment point against the wall and make the cut from the point to the edge. Next, make a final trimming, with the reserve from the edge of 0.5-1 centimeter for thermal expansion of linoleum.

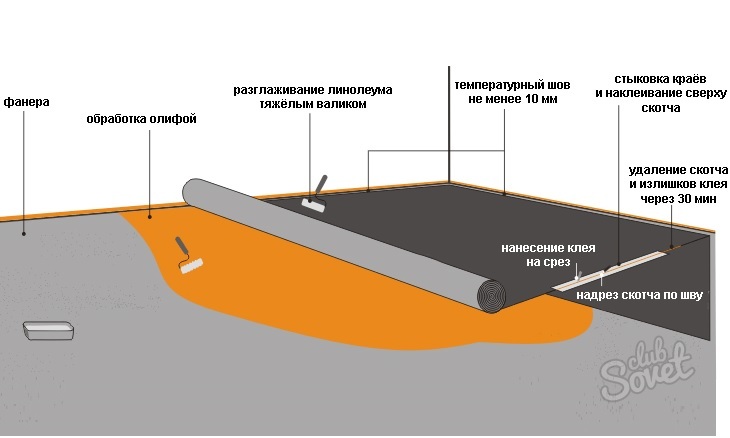

In the case of combining two pieces of linoleum, it is necessary to glue both sides of double-sided adhesive tape to prevent displacement of the drawing.

Securing linoleum

If linoleum laid out with one piece, it will be enough to press the skirting and thresholds for doorways. And when under the Code of several parts were used, must be connected to a two-way tape or with special glue around the perimeter of the room. For bonding of joints is best to buy a transparent adhesive to go to be seen.

Next, attach the plinth and sills. For uneven walls, use plastic moldings, they repeat the irregularities of the walls, and they can hide the wiring. After using dowels and screws screwed sills. At the end inserted midway through the floor.

We hope you useful tips on laying linoleum.